Ecomaru (Purging compound using glass wool)

Outstanding contribution to revenue increase with even elimination of disassemble-machine-cleaning.

1 Secures high yield of 100% of similar level with powerful elimination of carbides (black specks), which even leads to elimination of periodical disassembling machine for full cleaning in many uses cases.

2 Overall purging cost reduction with less purging time with no need to double clean (conditions may apply).

3 Environment friendly with max of 50% reduction of amount used and waste.

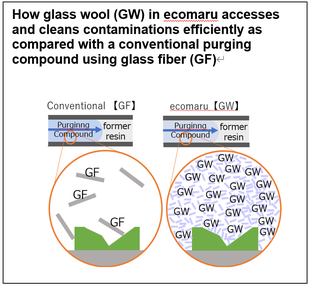

Glass wool mechanism in purging

Introduction of ecomaru

Ecomaru, a series of purging compound made of a resin filled with glass wool (GW), was first introduced in Japan in 2018 from the maker Nanodax (Tokyo, Japan). Yasukawa is the first distributor appointed by Nanodax.

Ecomaru cleans strongly and thoroughly contamination (black specks (carbides) and color) inside mold injection machines, with less waste and less odor.

In many use cases, because of its unprecedented performance, ecomaru is even replacing disassemble-machine-to-clean process (conditions may apply). In such cases, the time to complete the cleaning work had decreased from two to three days to merely an hour.

We are proud of ecomaru being an upcycled product from glass wool and contributing to SDGs created by the United Nations.

Free ecomaru samples are available to overseas markets, as well.

For inquires please contact us using the form available in our inquiry page.

100 % owned patents realizing distinctive performance of ecomaru.

Originally the technologies for producing resins filled glass wool were codeveloped by Nanodax and MAG-ISOVER K.K. a subsidiary of Saint-Gobain SA in France (glass and chemical material manufacturer), and now all the technologies and patents are 100% owned by Nanodax after all were transferred from Sain-Gobain Group. Currently, Nanodax owns 9 patents in Japan, 17 patents in 11 overseas countries, and 6 PCT pending.

Grades of ecomaru

We have a series of ecomaru to meet customer requirements.

Please inform us of your needs (resins, color of resins, MFR, machines and current purging method used), and we can give advice on the grades and purging process.

Introductory videos

Powerful and thorough cleaning power, thanks to glass wool mixed with one and only patented process. The solution for plastic injection industry seeking higher yield and profit. Try your self!

Tests results